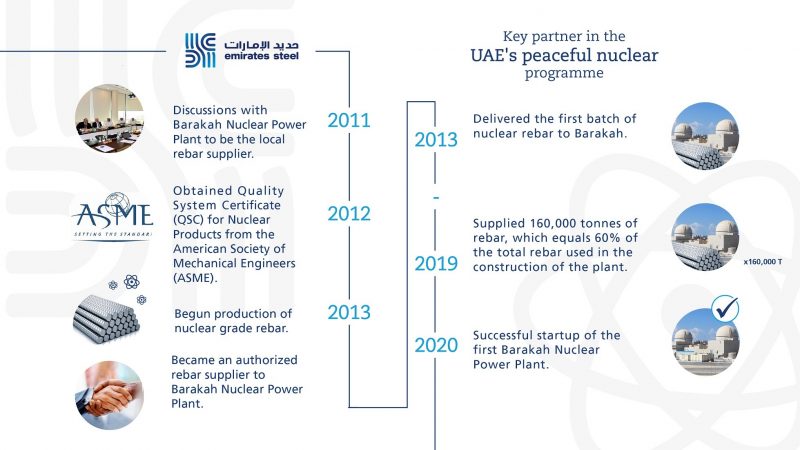

Emirates Steel a Key Partner for the UAE’s Peaceful Nuclear Energy Programme

Nuclear Energy

September 8, 2020, 11:40 am

- Emirates Steel worked with ENEC for the ten-year construction period of the Barakah Nuclear Energy Plant

- Company supplied 60% of project’s rebar requirements

- A major achievement in meeting stringent global nuclear energy construction standards

Abu Dhabi-UAE: 9 September 2020 – Emirates Steel, the leading integrated steel plant in the UAE, has proudly announced its contribution to the national achievement of constructing the Barakah Nuclear Energy Plant, the first peaceful nuclear plant in the Arab World. Emirates Steel supplied 160,000 tonnes, equivalent to 60% of the Q-class and S-class rebar material used in the construction of the plant.

Emirates Steel has been a partner of the Emirates Nuclear Energy Corporation (ENEC) from the outset of the Barakah project some ten years ago up to the historic start-up of the first of its four reactors in early August. Its specialised teams worked for two years with ENEC’s dedicated Business and Industrial Development Team to ensure that the company’s quality assurance and production processes met the stringent and precise global nuclear standards of construction required for such a challenging undertaking.

HE Engineer Saeed Ghumran Al Remeithi, Chief Executive Officer of Emirates Steel, said: “Emirates Steel has played a significant role in the UAE’s industrial sector for decades, and we are keen to contribute to the transition of the energy sector now underway in Abu Dhabi and the wider UAE. We seek to engage collaboratively in such high profile and ground-breaking projects that contribute to the development of Abu Dhabi’s diversified economy. We are proud to have been a key strategic partner with ENEC from the very beginning of the process to bring peaceful nuclear energy to the UAE, and have worked relentlessly to ensure the conformity of our products to global nuclear quality standards.”

In 2012, Emirates Steel obtained the Quality System Certificate (QSC) for Nuclear Products, known as ‘Q Class’, from the American Society of Mechanical Engineers (ASME), which is a prerequisite for the products used in nuclear energy plant construction. In 2013, the company delivered its first batch of rebar products to the Barakah plant project site.

HE Mohamed Ibrahim Al Hammadi, Chief Executive Officer of the Emirates Nuclear Energy Corporation (ENEC), added: “The nuclear energy industry has some of the most stringent quality, technical and risk management standards in the world, and Emirates Steel is a shining example of the world-class standards that can be achieved by home-grown companies. They have met and surpassed the continuous, rigorous and comprehensive evaluation processes required through the manufacturing process up to final delivery and installation at the project site. By supporting the development of a new source of sustainable energy, we are not only contributing towards the UAE’s energy needs for decades to come, but also contributing to its economic diversification and transition to a knowledge-based economy.”

Emirates Steel is the third largest steel producer in the Arab World, and has obtained many certificates of conformity for its high-quality products from various local, regional and international bodies, enabling the company to export its products to more than 40 countries.